Relocalize's Micro-Factories Eliminate Middle Mile, Cut Emissions

The future of supply chains hinges not on incremental improvements, but on a radical reimagining of how and where products are made. This conversation with Wayne McIntyre, CEO and Co-Founder of Relocalize, reveals the hidden consequences of our current, hyper-centralized manufacturing model: immense carbon footprints, inflated costs, and a reliance on inefficient, multi-stage distribution. By deploying autonomous microfactories at the point of distribution, Relocalize offers a compelling alternative that tackles these issues head-on. This analysis is crucial for business leaders, supply chain professionals, and anyone invested in sustainable innovation, offering a blueprint for achieving competitive advantage through systemic change rather than superficial fixes.

The Inconvenient Truth of the Middle Mile

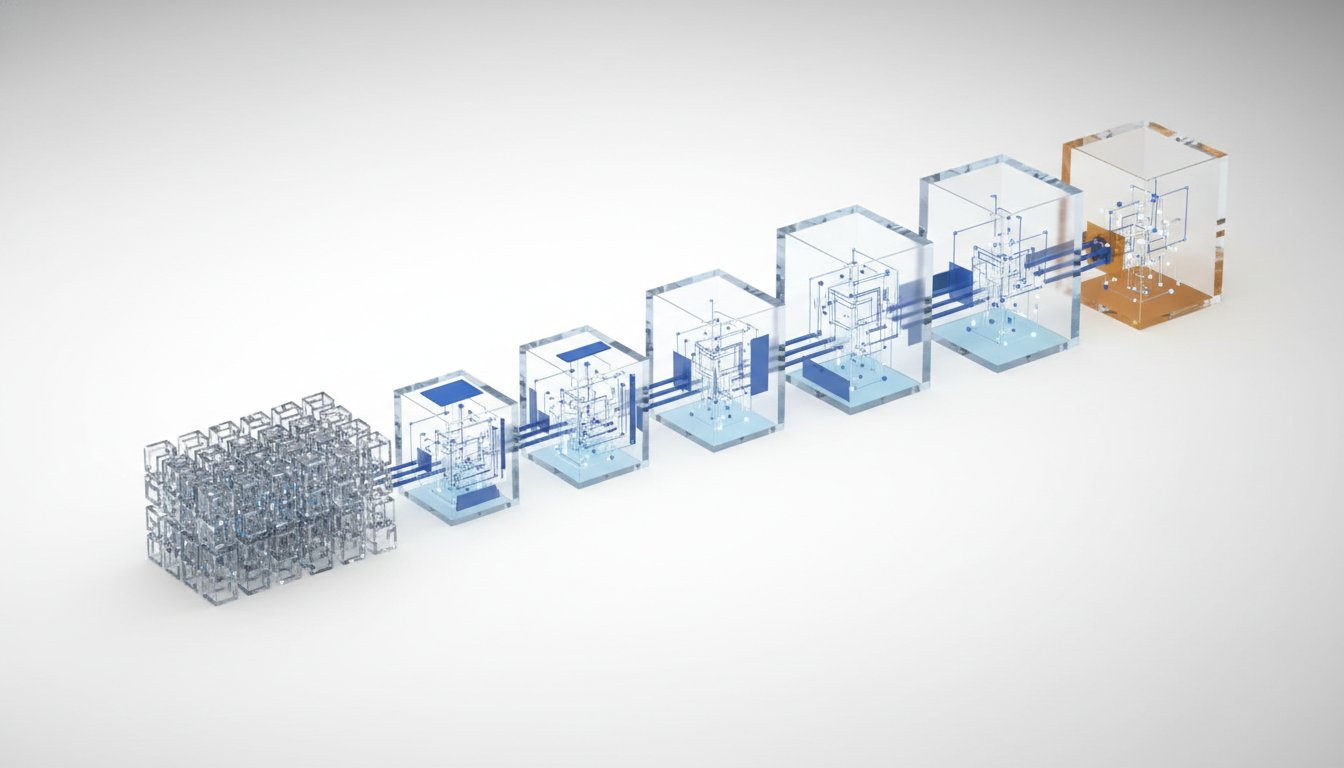

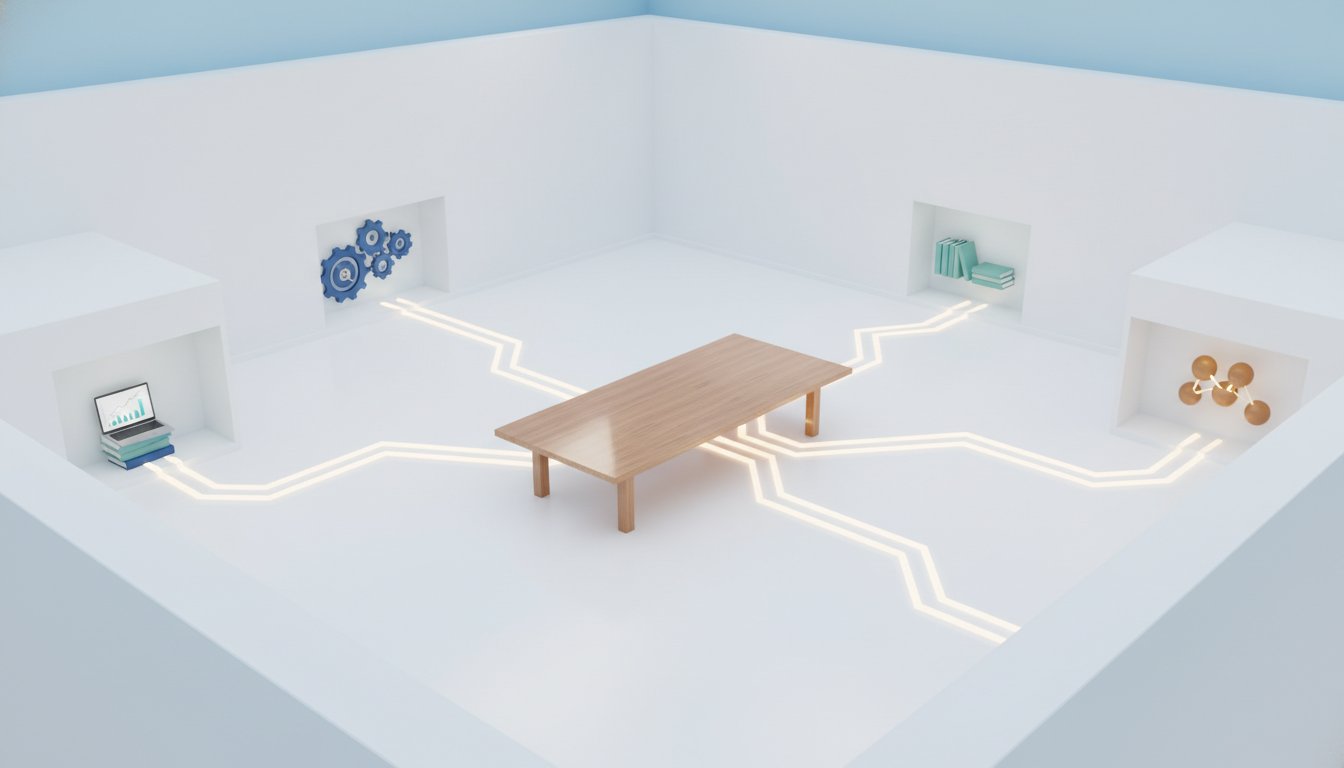

The prevailing wisdom in manufacturing and logistics is to achieve economies of scale through massive, centralized factories. This model, however, creates a vast, invisible cost: the "middle mile." Wayne McIntyre highlights how products, particularly heavy, water-based ones like packaged ice and cold packs, endure extensive trucking and cold storage from a distant factory to distribution centers. This journey not only inflates costs but also dramatically increases carbon emissions. Relocalize’s core innovation lies in flipping this model on its head. By establishing microfactories directly at distribution hubs, they eliminate the need for long-haul transportation of finished goods.

"You're cutting out all the trucks between the the centralized factory and the distribution center that's called the middle mile and also because you're doing it on demand if it's a refrigerated or frozen product you don't cut out all of the cold storage as well."

This "on-demand" production at the point of fulfillment means products are made only when needed, drastically reducing waste and the energy required for prolonged cold storage. The implication is clear: what appears to be an efficient, large-scale operation is, in fact, a system burdened by its own reach, creating environmental and economic inefficiencies that compound over time. The advantage here is not just a greener product, but a fundamentally more resilient and cost-effective supply chain, a payoff that accrues over years, not just quarters.

The "Dark Factory" Advantage: Efficiency Through Automation

The concept of a "dark factory"--a manufacturing facility that operates with minimal human presence, relying on automation and robotics--is central to Relocalize's operational efficiency. McIntyre explains that this approach allows for smaller, more agile production units. The demonstration system in Florida, described as the "world's first dark factory for the food packaging industry," served as a critical proof of concept. This wasn't just about lights-out manufacturing; it was about validating the technology and learning from customer feedback.

The transition from a smaller-scale demonstration unit to a full-scale commercial facility represents a significant leap. This scaled-up operation incorporates more robots, increased speed, and enhanced quality control, ironing out the kinks that are inevitable in early-stage development. This meticulous process of iteration and refinement, while demanding and time-consuming, is precisely what builds a durable competitive advantage. By investing heavily in R&D and operational polish before full commercial deployment, Relocalize is positioning itself to "crush the incumbents," not just compete. The immediate pain of rigorous testing and development yields a long-term payoff of superior product quality and operational reliability that competitors, who prioritize speed-to-market over foundational robustness, will struggle to match.

The Trifecta: Better, Cheaper, and Greener

McIntyre’s strategy for scaling Relocalize is particularly insightful because it targets the core motivators for businesses and consumers: cost and quality, with environmental benefit as a powerful, often decisive, bonus. He emphasizes that while some consumers may prioritize "green" products, the broader market is driven by value. By making products like packaged ice and cold packs "better, cheaper, and greener," Relocalize taps into a universal demand.

"The reality for extremely heavy products right now, so whether it's a beverage, whether it's a cold pack, doesn't really matter. You know, if you, other than marketing costs, the number one cost is logistics. The second largest cost is packaging. And so, you know, if we can remove the logistics and packaging, we remove a lot of the cold storage. And ultimately, if we can move from from plastic to paper, you're pulling out a whole lot of cost from that system while you're doing good."

This approach is described as "subversive" because it achieves impact not by appealing to altruism alone, but by offering a superior economic proposition. In an era of inflation and economic pressure, offering a product that is simultaneously more affordable and environmentally responsible is a powerful differentiator. This strategy acknowledges that broad market adoption--the key to significant, systemic change--requires appealing to pragmatic concerns first. The delayed payoff here is the establishment of a dominant market position built on a foundation of fundamental economic and environmental superiority, a position that is difficult for competitors to challenge without fundamentally altering their own cost structures.

The Pivot from Idea to Execution: A Necessary Evolution

The journey from a nascent idea to a commercial reality is fraught with challenges, a sentiment McIntyre articulates through a favorite mantra: "Ideas are easy. Execution is hard." This is particularly relevant as Relocalize transitions from its startup phase to commercialization. The team’s dedication, fueled by a shared vision and the inherent difficulties of building a novel business, has been instrumental. However, the skills and processes that drive a startup--often characterized by rapid iteration, firefighting, and a shoestring budget--are not the same ones that scale a mature business.

McIntyre acknowledges this shift, referencing the book title "What Got You Here Won't Get You There." The next phase requires building more robust processes, developing deeper team capabilities, and ensuring redundancy to mitigate risks. This transition demands a conscious evolution, moving from reactive problem-solving to a more structured, plan-execute-deliver model. The discomfort of this organizational growth--the need for more formal structures, potentially slower decision-making, and increased accountability--is precisely what will enable sustained impact. By embracing this evolution, Relocalize is investing in its long-term viability, ensuring that its innovative model can scale effectively and continue to drive systemic change.

Key Action Items

-

Immediate Action (Next 1-3 Months):

- Pilot Relocalize's packaged ice solution: For retailers and distributors seeking immediate cost reductions and carbon footprint improvements, engage with Relocalize to explore pilot programs for packaged ice.

- Investigate cold pack R&D: For meal kit, pharmaceutical, or other cold chain logistics companies, inquire about the timeline and potential for Relocalize's recyclable cold pack solutions.

- Share the "dark factory" concept: For manufacturing leaders, explore the applicability of autonomous, lights-out production within your own operations to drive efficiency and reduce overhead.

-

Short-Term Investment (Next 3-12 Months):

- Model middle-mile cost savings: Quantify the current costs associated with middle-mile logistics and cold storage for your water-based products. Use this data to build a business case for localized production.

- Explore strategic partnerships: For companies with significant distribution footprints, consider partnerships with Relocalize to co-locate microfactories at your distribution centers.

- Develop internal automation expertise: Invest in training and technology to foster greater automation within your existing distribution and fulfillment centers, drawing lessons from the "dark factory" concept.

-

Longer-Term Investment (12-24 Months and Beyond):

- Commit to system-level change: Rather than focusing on isolated optimizations, begin mapping the entire supply chain system for your key products to identify opportunities for radical redesign, inspired by Relocalize's model.

- Embrace the "better, cheaper, greener" trifecta: For new product development or existing product lines, prioritize solutions that deliver on all three fronts, understanding that broad market appeal is key to scaling impact.

- Foster an execution-oriented culture: Encourage and reward teams for moving beyond idea generation to rigorous execution and iteration, recognizing that sustained progress comes from doing, not just dreaming.